Technologies

E-paper Displays

Pros & Cons of ePD

E-paper Display vs Active Matrix TFT Color Display

Strengths

Weaknesses

- Ultra-low power consumption

- Ultra-wide viewing angles

- High readability – even outdoors

- Thin and lightweight

- Slower refresh time

- Limited colors

Our Strategies

- Ultra-low power display solution for industrial and IoT applications

- Three-color EPDs available in Red, Black, and White

Types and Market Trends

| Criteria | Type | Market demand |

|---|---|---|

| By Color | Black & White | -- |

| Red, Black & White | Increasing | |

| Yellow, Black & White | Niche | |

| By E-Ink Film | Aurora Mb | Increasing |

| Aurora -25 | Niche | |

| Spectra Red | Increasing | |

| By Timing Control Architecture | internal Timing Controller (iTC) | Increasing |

| external Timing Controller (eTC) | -- | |

| By Refresh Mode | Whole | -- |

| Partial | Increasing |

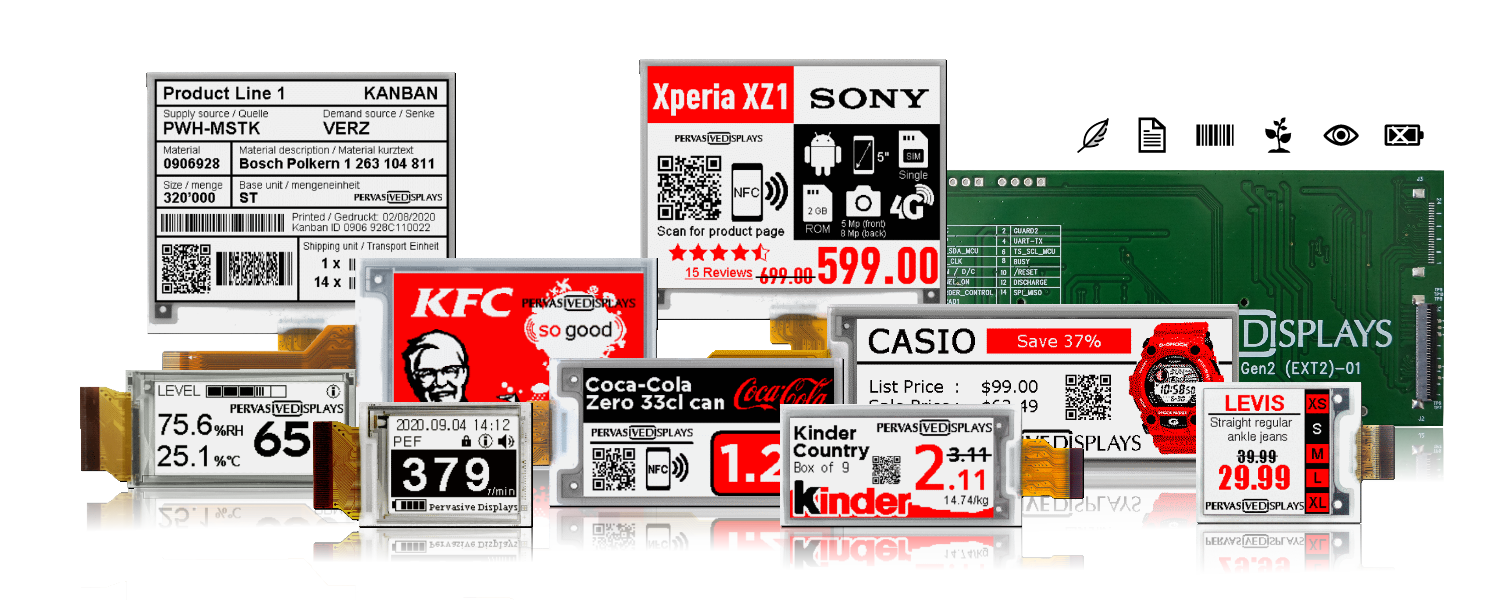

EPD products at Pervasive Displays (Source: Pervasive Displays)

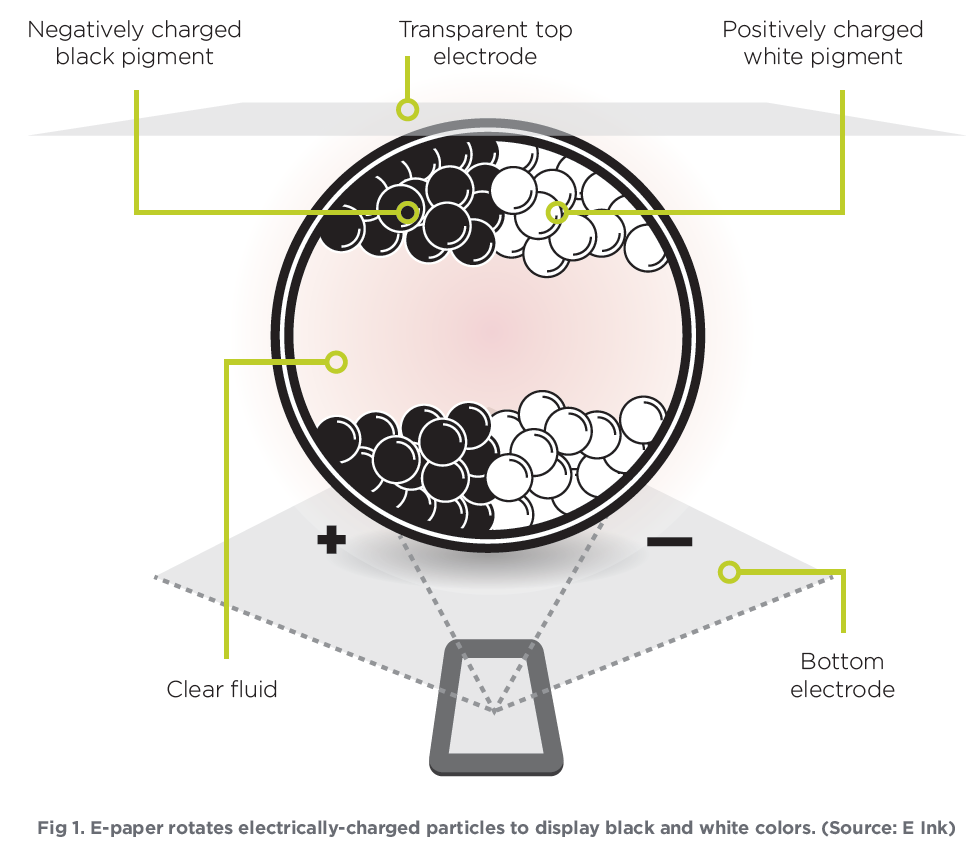

How EPD works

E-paper (also called ePaper) is an electronic display technology that mimics the appearance of paper. Using the same inks as the traditional printing industry, E-paper Displays (EPDs) have tiny capsules filled with negatively charged black and positively charged white ink particles. When the proper charge is applied, an EPD creates highly detailed images with the contrast ratio and readability of printed material.

Three-color EPDs, such as those capable of displaying black, white, and red, are a little more complex because particles in those three colors must all carry different charges, and thus consume relatively more power.

E-paper is bi-stable, meaning no power is required to maintain an image after it has been formed. It's also reflective; like traditional ink and paper, it uses reflected light to make its image visible, rather than relying on a backlight. The absence of a backlight also means EPDs can be thinner and lighter than LCDs. These low-power, low-processing requirements and thin, light characteristics enable EPDs to present much richer information directly on the device, without the power or processing requirements of a traditional TFT LCD.

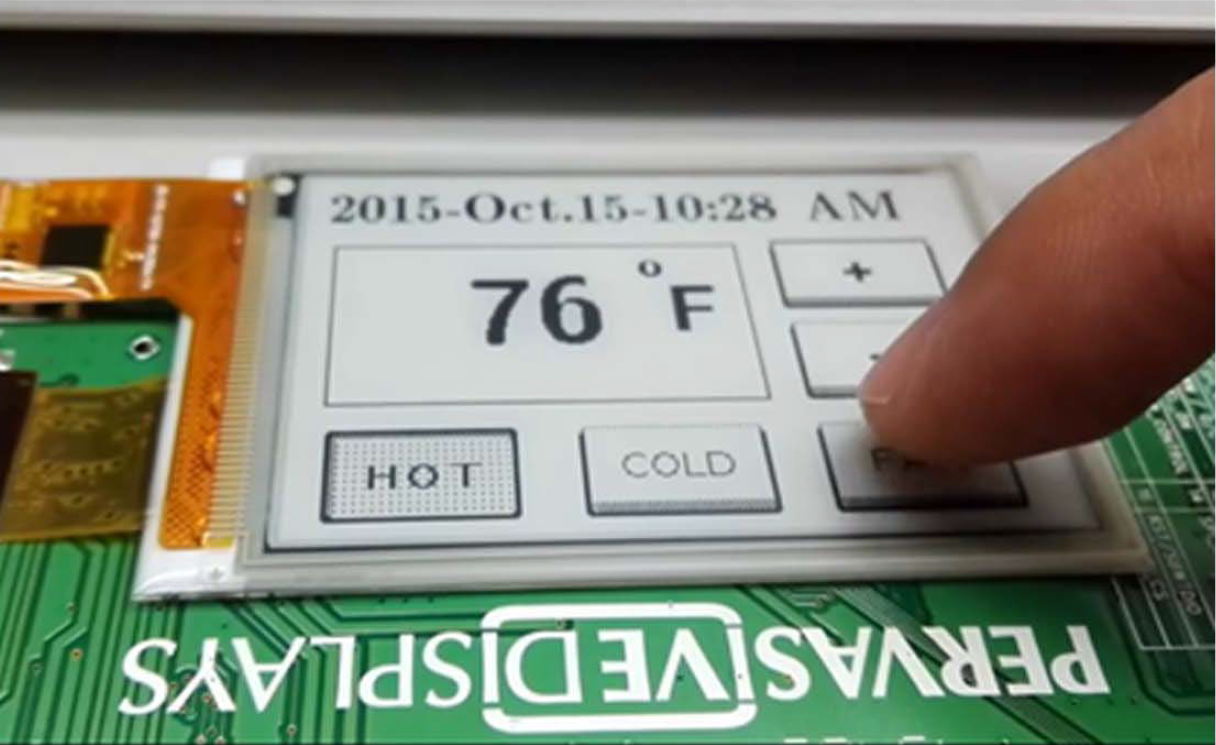

While EPDs are bi-stable, they take about one-to-two seconds to update typically so as to be cycled without image ghosting. This refresh rate is sufficient for static image displays, such as signage, or displaying infrequently changing data. But for user interfaces, animations, or frequently changing data, it may need a faster response.

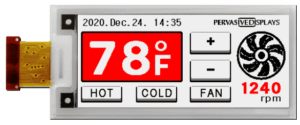

A 2.7-inch e-paper module with capacitive touch overlay, which demonstrates a responsive user interface for a thermostat utilizing partial updates. (Source: Pervasive Display)

By using partial updates – where only part of the display is updated at a time – the image can refresh more rapidly, enabling designers to implement animations or deploy user interfaces. With partial updates, image refresh time can be decreased to as short as a few 100 ms, depending on the refreshing area and the type of image being displayed. Besides, partial updates eliminate the "flash" or "blink" effect during full-screen updates.

Ultra-low power EPD and wireless communication

With its low-power, bi-stable characteristics, E-paper is a natural fit for battery-powered wireless devices that would be unable to power traditional LCDs. The bi-stable nature of E-paper screen updates harmonizes perfectly with loT-optimized wireless protocols, such as Bluetooth Low Energy, by enabling battery-powered devices to maximize time spent in sleep mode.

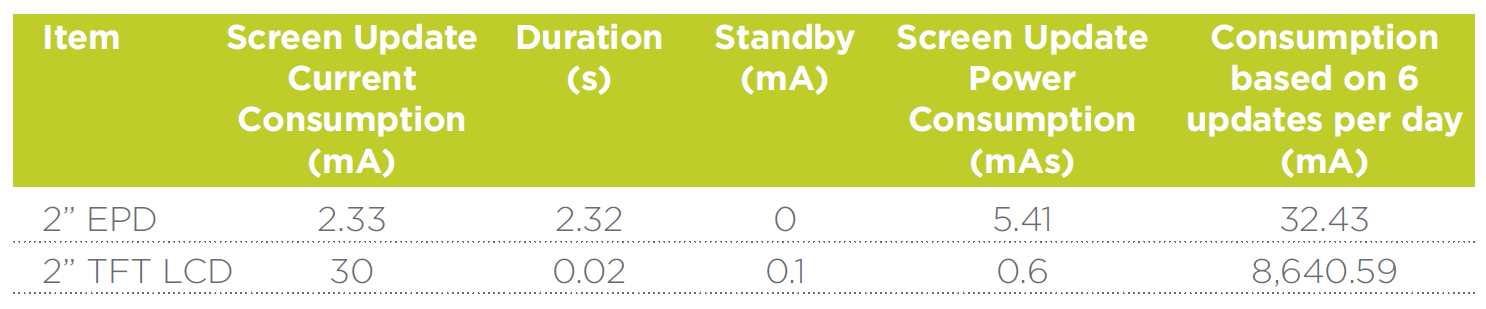

A comparison of energy consumption:

E-paper is far less power-hungry than traditional LCD screens

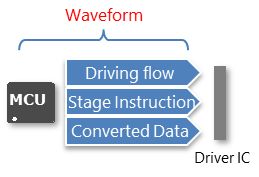

Wireless communication can also be used to update the EPD from the cloud, creating novel applications. Electronic shelf labels in a retail store can be updated from a centralized location, making price management much more efficient and dynamic. Wirelessly connected EPD signage around a building can similarly be updated easily and remotely, to reflect real-time room occupancy, for example. Badges with EPDs can change the information displayed, based on location-awareness.

EPD also complements well with RF-based wireless technologies. RFID (Radio-frequency identification) tags, designed for easy, automated asset tracking, need to be machine-readable. EPD can be used in conjunction with RFID to create visible tags for asset tracking, logistics means, or manufacturing, with a human-readable window into the data stored on the device.

Machine/human-readable EPD complements RFID, NFC, barcode or QR code.

(Source: Pervasive Displays)

How to choose E-Ink films

There are different types of E ink imaging film suitable for various operating conditions as summarized below:

| E ink film type | Alias | Colors | Operating temperature |

Storage temperature |

Remark |

| Aurora Mb | V231 | black, white (BW) |

0°C to +50°C | -20°C to +60°C | Our most subscribed display platform. Suitable for most indoor operating conditions. Support partial updates. |

| Aurora -25 | V430 | black, white (BW) |

-25°C to +30°C | -25°C to +60°C | Suitable for freezing operating conditions. |

| Spectra Red | R2.0 | black, white, red (BWR) |

0°C to +40°C | -20°C to +60°C | 3-colors pigments inside. Taking longer time to complete a refresh. |

Evaluations from aspects below can also help you determine the best fit for your application:

–Refresh cycle

- Note that EPDs are suitable for refresh cycles (global update, full screen update) from tens of seconds to minutes.

- Fast update rate (partial update – few hundred mini-seconds) is feasible but please share your requirements with us for further support.

- An EPD is more suitable for applications where a static image is maintained without electricity and doesn’t need to be refreshed frequently.

–Temperature & colors

- Determine whether the operating temperature or color is the primary requirement for your product or use case.

- If having red as one of the EPD colors is a primary requirement, note that Spectra EPDs cannot be operated at sub-zero temperatures.

- If you need your product to operate under 0℃, the Aurora -25 EPD (black and white) will be the only suitable EPD.

- We recommend selecting Aurora Mb if it is not essential that you have a three-color display.

Driver comparison of iTC and eTC

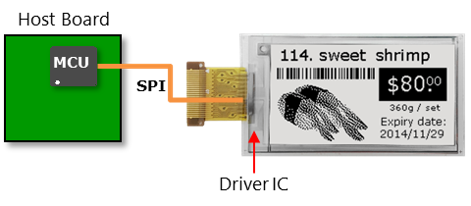

To drive an EPD, there are two types of controllers: iTC and eTC.

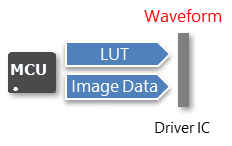

iTC stands for internal timing controller, which means the driving waveforms (LUTs, lookup tables) have been pre-programmed in the driver IC. Developers just need to send image data and update command to complete the screen refresh. And if developers need special support to change the waveforms, extra LUTs can be sent externally.

On contrary, eTC refers to external timing controller. Following the driving guide by Pervasive Display, developers can fully control the driving flow and stage from the MCU, but need to send converted image data at each specific stage.

The table below illustrates how these two driver types work.

| Driver type | iTC (internal timing controller) | eTC (external timing controller) |

| EPD with host board |  |

|

| Waveform location |  |

|

| Driving waveform | Embedded in driver IC (CoG) | Controlled by MCU |

| Customization / Design flexibility | Normal | Higher |

| Design-in effort | Easier | Normal |

| Power consumption | Normal | Lower |

Applications

Before going into more details about the application of EPD technologies, let’s take a quick review on their technical characteristics and related features.

Table of the characteristics and related benefits for ePDs

| Characteristic | Related benefit |

|---|---|

| Bi-stable image | No energy required to maintain content on the display |

| Reflective display | Ease of readability and no backlight |

| Three-color potential | Can display a combination of three colors among white, black, red, and yellow |

| Full/partial updates | Partial: only update the parts needed – fast response and low power |

| Driving - iTC | Offer pre-programs for iTC-equipped EPDs for easy deployment |

| Driving - eTC | Integrate with user’s low-power MCU for overall efficiency |

| Touchscreen-capable | Can add touchscreen on demands |

| Rigid | More impact-resistant. Can operate in -20 ~ 50°C environments |

With features of EPDs in mind, there are some criteria to help you decide whether EPDs suit your application. In summary, an EPD will be a good fit if several of the followings apply:

- Need to provide easy-to-read information for humans or machines

- Require higher resolution and/or more flexibility on the content to display over a passive segment LCD

- The information to display is relatively static - i.e. the data changes infrequently, or the person viewing it doesn't need it to be real-time

- There is no main power connection so the device must run off a battery

- A thin and/or lightweight display is required for your application

Applications of EPDs in practice have gone much further beyond E-paper readers. To provide a snapshot of the whole picture, here are several typical use cases where EPDs suit the best:

- Retail shelf labels: Replacing paper tags or LCD segment displays

- Logistics tags: Human- and machine-readable

- Remote IoT sensors: adding a display where there was none

- In-home safety equipment: Improving battery-powered alarms

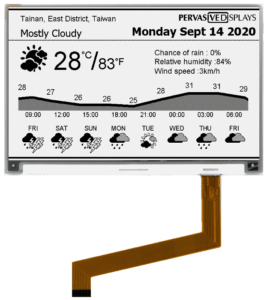

- Domestic weather monitoring stations

Electronic shelf labels – easy to update and attention-grabbing in red/black/white

Weather monitor – intermittent update

Weather monitor – intermittent update

Source

How e-paper works. (2020, April 08). Pervasive Displays. https://www.pervasivedisplays.com/how-e-paper-works/

Editor: Charis Chen